Reason1

Meticulous hygiene management

Hygienic conditions are thoroughly managed in the factory floor where confections and snacks are manufactured in Japan. Small metal objects that could get mixed into the products are strictly prohibited from bringing into the factory. After changing into work clothes at the factory, workers use an automatic brush to clean their shoes and a lint roller and vacuum hose to remove hair from their clothes. Next, they pass through an air shower that blasts a powerful stream of air to remove dust. They then check themselves in a mirror, once more use the lint roller to remove dust, and use alcohol-based hand sanitizer. It is only after this strict process that the worker can finally enter the factory. Metal detectors are used during production to check for foreign materials carefully and meticulously.

Reason3

Individual wrapping and special attention to hygiene

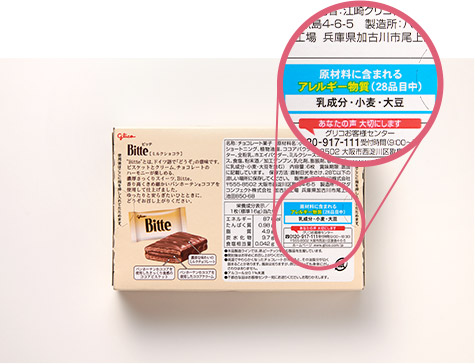

Products are often individually-wrapped, as is distinctive of Japanese treats. This is more sanitary when sharing with family or friends and has the added benefit of keeping your treats fresh longer. The designs are often cute and depict the brand’s worldview, and the packages are both highly functional and informative. While devising ways to enhance safety and functionality, no efforts are spared to build the brand and meet consumer expectations. Everyone’s story is different, and manufacturers want eating treats to be a moment of happiness for each individual. Manufacturers are constantly working to increase quality in safety so that you can enjoy Japanese confections and snacks with peace of mind anytime, anywhere.